H2: Introduction

When it comes to precision manufacturing, CNC Precision Turning Parts quality is of prime importance and will directly affect the efficiency and quality of end-use product functionality. Notwithstanding its paramount importance in precision manufacturing and industry standards, the CNC turned parts industry is always confronted by a significant and grave challenge in terms of low yields because of dimension and surface defects that increase rework costs and project timelines to a considerable extent.

The reason inixa-dependency is rooted in traditional quality control because manual sampling lacks holistic real-time monitoring of the dynamic machining process and therefore is associated with a significant risk of delayed defect detection and identification. Therefore, in order to meet and counter this basic requirement gap and ensure every single part is within stringent specifications, a testing program involving real-time process monitoring along with Statistical Process Control is a prime necessity in CNC turned parts industry and is exoglossified in this paper.

H2: Why is Precision Testing the Core Guarantee for CNC Turned Parts Quality?

Precision testing is much more than a final step of inspection; it’s an integral core assurance system throughout manufacturing when it comes to the production of CNC Precision Turning Parts. It translates abstract design blueprints into quantifiable and verifiable physical reality through high-precision equipment like CMMs, which allow for control at micron and sub-micron level tolerances. Recent research into Real-time Monitoring in Precision Turning, published in the International Journal of Machine Tools and Manufacture, has demonstrated that inline test data can be dynamically fed back into the CNC system to optimize tool paths and compensation parameters in real-time, thereby maintaining machining stability proactively. The absence of rigorous testing, on the other hand, entails considerable risks.

For example, a turning part for precision hydraulic spool, if its roundness or cylindricity is not strictly verified, can lead to internal leakage and pressure instability, culminating in the failure of the system as a whole. Therefore, systemic Precision Manufacturing Inspection is by no means only a tool for finding defects but a crucial engine for preventing issues, continuously refining processes, and directly driving higher yield rates, hence forming an indispensable component of any robust Quality Assurance Services.

H2: What are the Common Quality Challenges in the CNC Turning Process?

Despite the highly automated process of CNC turning process, many variables could result in differences of quality. Ideal Manufacturing Process Control must therefore identify and overcome such challenges for the production of highly precise precision turned components with consistent quality.

H3: Inherent Variables in the Dynamic Machining Process

The quality of the turned components is affected by a number of dynamic variables. The major one is progressive tool wear, which changes the cutting geometry, leading to drift in dimensions and surface finish. The thermal deformation of the work piece is also very critical. The major cause of thermal deformation is the generation of heat due to cutting operations, which causes micron-scale expansion of the cutting machine tools. In addition, the machining vibration or chatter is the major cause of surface patterns that contribute to the generation of surface roughness.

H3: Attaining Early Warnings by Means of Process Control and Standards

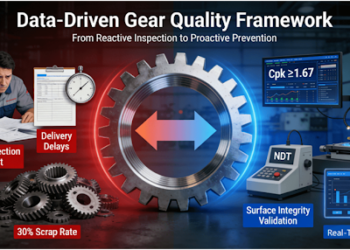

In order to meet these challenges, there has to be a paradigm shift from “reactive inspection” to “proactive prevention” and “in-process

l Application of Statistical Process Control (SPC)

SPC can prove to be a very useful technique for Manufacturing Process Control. By allowing the collection of data pertaining to certain crucial dimensions such as diameter or length values for plotting control charts, it becomes possible to distinguish between natural variations in processes as well as deviation trends. For instance, if certain consecutive values depict a trending pattern of up or down values, it may depict a pattern of increased tool wear that can depict an alert before the deviation from the specified values.

l Role of Frameworks in Standards & Certifications

Observing internationally accepted standards is basic if an efficient quality control system is to be achieved. Standards on testing machine tools, as outlined by organizations such as ASTM International, give scientific approaches on how machine accuracy should be determined. On the same note, manufacturing organization certifications such as ISO 9001 ensure uniformity of the control process all through from design to manufacture. To satisfy those who want to learn more, there is an extensive provided here: CNC Precision Turning Guide.

H2: How to Implement Effective Precision Manufacturing Inspection to Enhance Turning Efficiency?

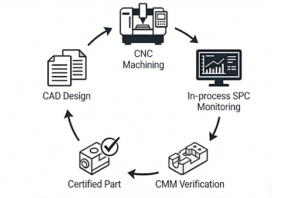

Effective Precision Manufacturing Inspection can be systematically achieved from sample to full production. It begins with “First Article Inspection,” where the first parts made by this new process undergo full measurement to ensure that the latest process settings are properly established. This marks the first error-prevention barrier in producing error-prone batches. While producing each batch, inspection protocol be upgraded to periodic inspection or even continuous inspection by adopting SPC. Modern Industrial Testing Solutions increasingly adopt non-contact measurement techniques that employ laser scanning and optical measurement.

These measurement techniques have high speed, do not affect the surface of the inspected parts, have the capacity to scan enormous 3D data, and are very appropriate for Rapid Prototyping Validation inspection. The entire process greatly accelerates the validation of validated designs to manufactured production. It has been shown in an analysis by CIRP Annals on the cost/benefit analysis of advanced inspection technologies in the field of manufacturing that coupling advanced inspection technologies both in-line inspection modes and offline inspection can minimize defect rates by 20% by early defect removal, directly increasing the efficiency of profits in manufacturing.

H2: How Does Rapid Prototyping Validation Optimize the CNC Turning Process?

Before entering bulk production, the stage of Rapid Prototyping Validation is an important step in this process before entering full production, as it helps to significantly optimize CNC turning services for the production of parts such as the precision turning of steel parts.

H3: Managing Risks and Costs in Design Iterations

By making functional prototypes and testing them, possible deficiencies such as design errors, interference in assembly, and performance-related issues could have been detected before making any investment in tooling and production. For instance, testing a steel gear for an automobile transmission could have shown areas of stress concentrations in the gear teeth design, which would have been remedied before initiating production and saving on potential costly recalls.

H3: Assuring Material and Process Feas

However, not all materials follow expected behavior under the conditions of a CNC turning process. Engineers are able to assess the real machinability of various materials such as stainless steel, aluminum, etc., their deformation points after heat treatment, and the end properties of the finished material in the prototyping phase of the project..

H3: Accurate Verification of Geometric Shape

For parts with complex profiles, special threads, or micro-features, the conformity between the drawing and the physical part will be very important.

l 3D Scanning and Comparative Analysis

This involves intuitive color deviation maps that are generated by comparing the completely captured geometry against the original CAD model using high-precision 3-D scanners. With this method, a complete overview is given of the key feature dimensional accuracy and overall form, way beyond what used to be possible with the sampling limitation of calipers.

l Speeding Up Design Finalization

According to the comparison results of the scans, engineers will rapidly decide on further modifications in the CAD design or optimization of strategies and tool paths for CNC turning services. This agile feedback loop ensures that the design is frozen as quickly as possible with a high degree of accuracy, going into volume production without hiccups. Such a project can be initiated by engaging the services of a professional service provider for CNC Turning. According to a Science Direct article on the role of prototype validation in Agile Manufacturing, “A prototype is one of the key links in the chain between design and manufacturing, which enables a rapid response.

H2: What Testing Standards Should Be Considered When Choosing CNC Turning Services?

When picking a partner for CNC turning services, one of the most important aspects of the evaluation process is the testing capability and quality requirements. Firstly, general tolerance requirements must be considered, starting with thestandards that most companies follow, namely ISO 2768, general geometric tolerances, which gives one of the most authoritative interpretations of general unspecified drawing tolerances. Industry-specific requirements, on the other hand, take a much greater priority, with aerospace being AS9100/EN 9100, the automobile industry being driven forward with IATF 16949, while the production of healthcare devices requires the following: ISO 13485. The key is that the company in question has set in place a thorough Quality Assurance Services program in support of the design and production of the product.

For instance, the AS9100D certification of JS Precision ensures that their components are of aerospace standards. An effective checklist to assess the suppliers must consider the following: If they issue First Article Inspection Reports, if their processes are monitored through SPC, the availability of CMMs, and if complete inspection results are provided with the shipment. For ease of understanding for the authorities, the guiding principles of ISO 9001 Quality Management System form the base for specific industry standards.

H2: Conclusion

Summarily, it could be noted that the solution for overcoming the bottlenecks in the quality offered by CNCturned parts lies in the diagnostic process of systematic and forward-looking testing. Whether it is monitoring, SPC testing, quick verification, and certification according to the highest standards in the industry, a comprehensive and holistic testing strategy turns the process of quality inspection and management into a proactive process rather than a reactive process, and in effect, their costs in performance and execution. It is the right moment for you to reassess your testing process if you have been working on zero-defect strategies.

To get a tailored testing solution for your project to ensure the quality of your precision components, contact our testing experts today.

H2: Author Biography

The author is a senior expert in precision manufacturing and test technology with more than a decade of working experience, focusing on advanced application in CNC turning-milling compound machining and precision measurement. Having participated in several international collaborative projects in the fields of aerospace and high-end medical devices, the author is committed to pushing the boundaries of precision and efficiency in manufacturing through innovative solutions for testing.

H2: FAQs

Q1: How does precision testing impact the cost of CNC turning?

A: Precision testing greatly diminishes material waste and rework by the early detection of defects. Data indicates that through an effective test system, up to 15-20% overall defect reduction is achievable; which leads to large cost savings especially in high-volume production.

Q2: What is the minimum testable tolerance of CNC turned parts?

A: Tolerances as tight as ±0.005mm or even stricter can be checked by employing ultra-precision CMMs or laser interferometers. However, the achievable precision depends on material properties, machine capability, and environmental control, with adherence to international standards like ISO being the baseline for optimizing test accuracy.

Q3: Which materials are appropriate for validation through rapid prototyping?

A: This validation can be applied to most of the machinable materials, including but not limited to metals such as steel, aluminum, and titanium alloys, and engineering plastics. For example, steel part precision turning validation may find heat treatment deformation defects much earlier to ensure the design will be feasible in this respect.

Q4: How to choose a trustworthy CNC turning service?

A: Some key factors one would want to verify would be their quality certifications such as AS9100D, IATF 16949, whether their inspection equipment inventory is calibrated, and reviews of some sample inspection reports. First priority should go to suppliers who can provide complete quality data services, from the first article to full-process monitoring.

Q5: Can testing handle components featuring complex geometries?

A: Yes. Modern 3D scanners and 5-axis CMMs have been designed specifically for the inspection of intricate free-form surfaces with irregular contours. However, in cases where the part geometry is extremely complicated, a custom fixture and inspection program developed in collaboration with the service provider may be required.