H2: Introduction

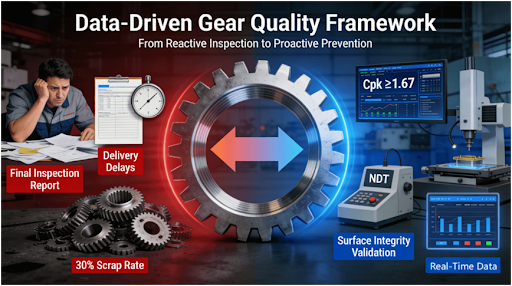

In the realm of precision manufacturing, the cost of failurefor components such as gears is immeasurably vast. While many companies in the industry rely on the mere inspection report alone, they are still faced with the challenges of unexpected product failure, shipping delays, and quality variations in the supply chain. The prevalent problem in the industry may be attributed to the underlying shortcoming in the quality verification methodology. The underlying problem is the general reactive nature of the traditional quality verification process, rather than being forward-thinking and monitoring prevention. This means that issues are being found too late in the process due to the substantial cost of correction.

This article presents a comprehensive approachthat goes beyond mere measurement and incorporates validation from the very beginning of the manufacturing chain. It combines all conceivable aspects such as audits of the suppliers and even advanced non-destructive testing to ensure reliability and predictability of the supply chain right from the beginning.

H2: Why is SPC the True Barometer of Sustainable Gear Quality?

Final inspection, although required, is but an inspection in time. Resilient gear quality begins with the stable qualified process, which can be quantified by the use of Statistical Process Control (SPC). Relying exclusively upon sampling inspections overlooks the significance of the trends and variations that happen in the course of manufacture.

H3: 1. From Snapshots to Continuous Monitoring

Contrary to random sampling, in SPC, actual data for critical gear dimensions like tooth profile (involute) or lead (helix) angle is tracked in real time. Using data points from every gear or at regular intervals, it is possible to plot the stability of the processthrough an SPC. Thus, rather than a photo or a snapshot, a motion picture or a continuity of the process of gear manufacturing enables early detection of a trend—and before non-conforming gears can be produced—one can act upon the data. It is a basic requirement for superior gear manufacturing, as described by the guidelines offered by the National Institute of Standards and Technology (NIST) for statistical quality control.

H3: 2. Decoding Process Capability: The Meaning of Cpk ≥ 1.67

One of the most common metrics extracted from an SPC is the process capability index, or Cpk. For mission-critical parts such as gears, a Cpk factor of 1.67or better for critical features is typically the standard in the gear industry. A Cpk factor of 1.67 or better indicates that the gear-making process is not only centered within the specification limits, but it also has at least a six-sigma margin, and is therefore highly capable of producing gears within specified limits. The best way to judge the quality capability of a prospective gear supplier is by examining their actual SPC charts and Cpk factors for their most important gear characteristics.

H3: 3. SPC as a Common Language for Supply Chain Transparency

The incorporation of a strong SPC process alters the relationship dynamic between suppliers and manufacturers. An SPC process creates a discourse in terms of objectivity and data, rather than reliance on subjective forecasts or ideas. The incorporation of stronger performance data from suppliers to manufacturers creates a relationship dynamic founded upon collaborative improvements. This assists in fostering a relationship dynamic governed by an understanding among all parties in which quality production is maintained from start to finish.

H2: What is the Role of Advanced NDT in Validating Surface Integrity?

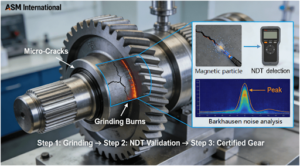

A gear may be perfect dimensionally, yet it can still be a ticking time bomb. It is the integrity of a gear’s surfaceand sub-surface that really determine its durability. Grinding and heat treatment processes are the very things that could compromise these qualities. Microscopic cracks, grinding burns, or other metallurgical defects are not visible to either the naked eye or conventional micrometers, but they have a disastrous effect on fatigue life.

l How to Find the Hidden Threats to Gear Lifetime: Manufacturing processes such as grinding produce high temperatures that, if not kept within proper bounds, result in metallurgical changes called grinding burns. Such grinding burns can form untempered martensite, a brittle phase that serves as a nucleation site for cracks. On a related note, micro-cracks may be set up by heat treatment. These defects are insensitive to dimensional inspection methodsand will inevitably promote catastrophic failure in service due to cyclic loading. These aspects make verification of surface integrity imperative for gears being used under severe conditions.

l A Toolkit for Invisible Flaw Detection: It is here that the application of Non-Destructive Testing proceduresassumes its importance. Techniques such as Magnetic Particle Inspection can be used to detect surface cracks, and Eddy Current Testing is very effective regarding the detection of near-surface flaws and differences in hardness. For the most critical parts of gears, more sophisticated techniques such as Barkhausen Noise Analysis are employed to detect grinding burn and residual stresses. All the above procedures mentioned under the ASM International Handbookare essential to ensure that the material properties of the gear meet the specified standards.

l Integrating NDT into a Holistic Quality Regime: Advanced NDT procedures must play an integral part in the overall quality plan for such critical gears instead of remaining an afterthought. By establishing precise NDT specifications according to gear use and failure mode analysis, manufacturers will have a means of ensuring that such critical inspections become carried out on a systematic basis. It is also necessary that the results of such NDT be traceable, establishing a true pedigree in terms of overall quality, which goes beyond the usual dimensional verification.

H2: Deciphering a Supplier Audit Other Than ISO Certification

ISO 9001 certification is only a basic qualification, and it basically translates to “this system existed” rather than “this system worked well.” The true high-performing supplier is one that executes its quality processes rigorouslyon a day-to-day basis on the shop floor. The deep dive audit on a supplier needs to see beyond all these certificates to examine “living, breathing” quality culture.When conducting a systematic selection process for gear machining suppliers, a detailed audit checklist is crucial, as thoroughly explained in this precision gear machining guide.

H3: 1. The On-The-Ground Audit Checklist

A credible audit will examine a number of important sectors. These will include checking their records for calibrations in precision equipment such as gear measurement centers, to ensure that this data is current and traceable back to a country standard. For a company dealing with heat treatment, checking their special process accreditations, such as NADCAP standards, is important. Critically, it’s useful to examine how a company handles traceability in materials, can a company trace a completed gear back to its original mill certificate? Lastly, check their non-conformance procedure; a sound method akin to an 8D report will highlight a company’s respect for root cause analysisand a method to ensure problems are not recurrent in nature.

H3: 2. Assessing Technical Partnership Capability

However, in terms of checking the box, in addition to examining the supplier’s ability to be a technology partner, the audit should also determine the quality of the engineering involvement of the supplier’s engineering staff in Design for Manufacturability (DFM)analyses of the gearing designs, offering value engineering recommendations related to materials of construction and processes to name a few. It’s engineering partnerships like these that help a supplier go from a supplier of parts to a strategic supplier for custom gearing machining services.

H3: 3. Constructing a Relationship Based on Data Transparency

The final objective of an audit is finding out whether the supplier conducts their business in radical transparency. Do they have confidence in being open concerning SPC statistics, process capability studies, and other statistical measures of quality? A supplier who trusts their processes would have no issues with this level of transparency.

H2: Is Performance in Challenging Scenarios a Guarantee by Just AGMA Compliance Testing?

Complying with AGMA (American Gear Manufacturers Association) specifications is necessary but always a starting point for achieving gear quality. The specifications contain some critical details with respect to geometric parameters, tolerance levels, and material usage. Yet, for electric vehicle transmissions or aerospace projects, for instance, following the AGMA specification blindly can prove perilous.

H3: 1. The Limitations of Standardized Testing

AGMA standards are intended to be generally applicable, but the AGMA standards may not reflect considerations related to a specific operating use and may not reflect proper considerations in a specific use because a gear may satisfy the AGMA Grade 10 standard but not be acceptable in a certain EV system with respect to certain defined profile changes. Such standard tests may not be representative in terms of proper use-related loadingconsiderations in a certain manner that may go undetected until it is reported as a problem.

H3: 2. The Need for Application-Specific Validation

For high-performance use cases, there could be a need for application-specific testing. This could range from customized noise and vibration (NVH) testing on custom rigs, life testing to simulate degradation over several years in a period of a couple of weeks, to tear-down analysis to verify for typical failure modes. This extent of validation is essential to verify that the gears function properly in their intended operating conditions, offering an element of comfort that is simply not provided by the standard validation report.

H3: 3. Partnering for Enhanced Performance Criteria

Thus, in selecting a supplier, a dialogue on their ability to support advanced metrology and performance verification capability beyond AGMA should be considered. Would they be capable of doing some specialty inspection work such as topographic analysison tooth flanks? Could they provide engineering assistance in understanding and developing these enhanced levels of verification? This type of partnership in performance criteria is key to success in a technologically advanced industry.

H2: What is the TCO Approach to Achieving Cost-Efficiency Without Compromising on Precision?

Generally, the cost of acquisition for a gear can be a mere fraction of the Total Cost of Ownership (TCO). At times, making a choice based on the supplier with the lowest cost can prove to be a very costly venture in terms of the rate at which gears have been scrapped, as well as potential failure at the customer’s location. Therefore, a good gear machining process would be one that strives for the highest possible value.

- The Hidden Costs of a Low-Price Strategy: Sometimes, the apparent lower costing could also offer some challenges, such as the inability to offer consistent quality, which means higher inspection costs for the company. This is also associated with low-quality engineering services, which could have designs that are more expensive to produce and could be less reliable. Sometimes, the challenges could nullify the initial costing advantage, hence affecting the bottom line for the manufacturer company.

- Quantifying the Value of Higher First-Pass Yield: A supplier who has sophisticated process control and high first-pass yields can provide gears that do not require any reworking or sorting. This jumps straight to better production flow, lower administrative costs related to quality, and lower inventory expenses. Customer satisfaction in terms of known required conforming partsevery time is an enormous albeit unmeasured financial advantage that helps in considerably lowering TCO.

- Investing in Reliability for Long-Term Savings: The fact that the suppliers who earn 16949 certification are committed to systematic process control is a highly effective stimulus for the reduction of TCO. The effective systems that a 16949 certification enforces are implemented in the context of the prevention of errorsand the improvement that is perpetually encouraged. The consequence is gears with a longer life and fewer failures, thus yielding the lowest cost from the onset to the end of life.

H2: How to Establish a Partnership Model for Long-Term Gear Manufacturing Success?

The final objective of developing and executing such a comprehensive framework is to shift the supplier relationship pattern from a transactional model to a partnering approach. Such a model is developed on the foundation of shared visions, open communication, and a joint passion for excellence.

H3: 1. Fostering Data-Driven Transparency

The partnership needs to have a foundation that can only come with data-driven transparency. It entails sharing data associated with performance, data that can measure the quality, and even some challenges for that matter. It enables the two parties to note potential areas for improvement.

H3: 2. Engaging In Joint Development And Value Engineering

The definition of a true partner is someone who participates in collaborative development efforts. This would mean value engineering in unison in order to optimize designs in terms of their functionality and manufactureability and also working together to develop a new process or a new specification. This way, through the expertise of the partner in manufacturing, innovation can speed along and perfection can be achieved in innovation because otherwise, perfection would not be so easy to attain.

H3: 3. Making a Commitment to Improvement

Finally, a partnership should embrace continuous improvement. This means having a structured feedback system in place and assessing each other on a routine performance evaluation basis to reach a better quality through shortening lead times and decreasing costs in a partnership to guarantee a stable future supply chain and not only a stable present supply chain.

H2: Conclusion

The process of ensuring quality in the gears is not a one-off exercise, but rather a continuous process of engineering. Through embracing the multi-dimensional approachset out in the above discussion, incorporating both SPC for the monitoring of the process, NDT for the integrity process, deep supplier audit for the capability of the supplier, and the TCO approach for cost-efficiency, the supply chain is in a position to proactively shift from being the recipient of quality inspections to being the joint providers of quality. This is the only way that the supply chain will attain operational excellence.

H2: FAQs

Q: What are the most important gears regarding the use of SPC?

A:For most helical and spur gears, the profile (involute) and lead (helix) are most important since noise, vibrations, and loading are largely dependent on them. The right supplier should be able to give an SPC chart with a Cpk ratio of at least 1.67in this respect. The dimensions before and after heat treatment are also extremely important with respect to distortion.

Q: What are the differences in quality verification between gear grinding processes and hobbing processes?

A:Gear hobbing is a roughing operation, and verification involves basic geometrical and size aspects. Gear grinding is a finishing operation used on high-precision gears (e.g., AGMA 12+). The verification requirements are comparatively tighter, requiring not only checking related to macro-geometry but also careful verification regarding surface integritythrough NDT techniques to identify grinding burns to attain a high-quality surface finish.

Q: Apart from cost, what are the next three most important factors for a supplier of gear machining?

A:First, process control capability, reflected in real-time data from a proper SPC program and a sound quality management system. Second, technical partnership capability, encompassing engineering support for DFM. Third, supply chain dependability, reflected in high on-time delivery record and open communication.

Q: Can you describe an example of value engineering in the production of customized gears?

A:One example that is generally applicable is optimization of materials, as well as processes. In a medium-duty usage, a supplier may recommend a changeover from through-hardened steel to a case-hardened steel with an optimized carburized layer depth as a suitable replacement option, which would cost less while providing required hardness on the surface along with a tough core.

Q: What should a good gear supplier provide in terms of documentation?

A:Expect a complete data set to include: material certification, heat treatment records, first-article inspection data with complete gear geometric information, SPC charts for key data, and certificates of conformance. In a regulated field, such traceabilityis mandatory.

H3: Author Bio

Conclusion drawn from this article has been obtained from the engineering team in LS Manufacturing, which has over 15 years of experiencein precision manufacturing. The organization helps engineers and researchers overcome challenges posed by complex components in aerospace, automotive, and industrial applications. They are certified in ISO 9001, IATF 16949, and AS9100Dand thus offer reliable and high-quality solutions to clients. To obtain a free project evaluation or a DFM analysis based on your needs, get in touch with their experts today.