In the modern era of rapid industrialization, automation frameworks serve as a pillar of operational optimization. Manufacturing plants and smart logistics hubs were specifically designed to help businesses increase their uptime while reducing energy expenditure and improving reliability. One important power supply component that is often overlooked for its importance due to lack of focus on it by the supplier is switching power supplies, which mostly people neglect.

Choosing the right switching power supply supplier greatly impacts individual processes and other components in the automation system. Every supplier plays such a vital role through broad line distribution and even through specialized partners like automation components inc. The right choice can greatly boost work processes, energy optimization, and the entire life of the system.

This article will discuss the value of the right supplier for industrial operations, the key criteria one should evaluate, and the sourcing choices that can help achieve your automation objectives seamlessly.

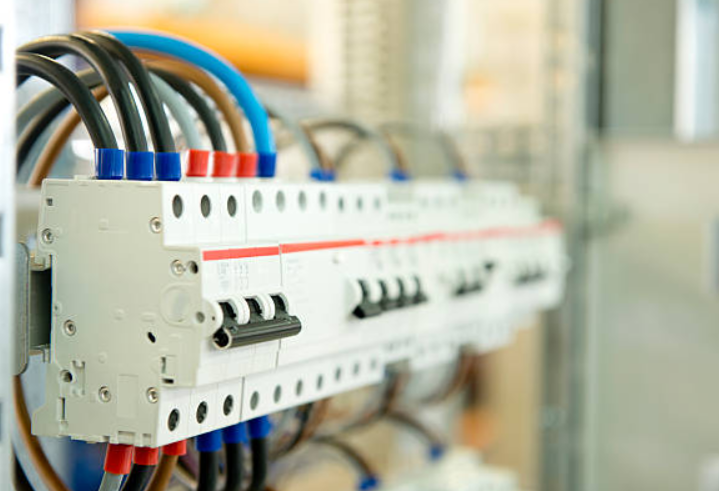

The Relevance of Power Supplies in Modern Automation

Like the heart is to a human, so the power supply is to an automation system. It transforms incoming AC power to the needed voltage level, in DC form, that the PLCs, sensors, motor controllers, and HMIs will use. Compared to linear models, switching power supplies are always preferred with high performance industries because of their efficiency, compactness, and ability to handle variable loads.

On the other hand, power suppliers do not offer the same quality. Using supplies that operate below standard will lead to overheating, maximum failure, and a beat up voltage. On the contrary, with a good supplier, there is bound to be seamless servicing during concerning issues, timely delivery, and compliance to set certification standards.

Every sophisticated automation company is aware that power surpluses and changes will cause down time which will greatly hurt production and profits. In case of need, guidance of a well versed supplier who specializes in switching power supply and inc. offer quality decisions.

How a Supplier Impacts Workflow Efficiency

While assessing workflow performance in an automated setup, the following factors has to be taken into account:

System up-time Match degree of the components Schedule of maintenance Kyber pharmacy Available replacement parts Stock-out of parts Each of them is dependent on the power supply and supplier chosen and has an impact on: For example, suppliers who keep granular inventory and have a… are less burdensome furnishing the documentation and certs required for compliance and integration. Suppliers with sophisticated inventory pipelines also reduce lead times and production bottlenecks. … In addition, purchasing a reliable switching power supply from Power Supply Integration and automation components inc. enables the buyers to have system level visibility and drives the optimization of each power supply to fit the active automation systems. … Essential criteria for choosing the supplier in an automation job. These days, procurement managers for industrial automation projects tend to streamline their vendor selection to a single checklist that sifts vendors based on cost.

keep in mind these five points that are just as important:

Technical Expertise: A supplier who provides power supplies is one case, another is who sells them in context of operations; that is applicable with good suppliers. Seek out for ones where engineering support and application advice are provided.

Product Range and Scalability: Whether your need involves a minute control cabinet or an extensive multi line facility, the provider should equip controllers with comparable and scalable power, form factor and mounting type options.Certifications and Compliance: For food, pharmaceuticals, and aerospace industries, power supplies have proprietary certifications such as UL, CE, and ROHS compliance. These requirements have to be met globally as the industry is regulated. It is the responsibility of the supplier to provide adequate documentation for compliance audits.

Lifecycle Support: The right supplier looks after long-term support from initial installation to the replacement of end-of-life products. This support entails firmware updates, troubleshooting support, backward compatible substitutions, and more.

Supply Chain Resilience: The electronics supply chain continues to be disrupted on a global scale. A reliable supplier has numerous sourcing approaches, inventory forecasting systems, or other strategies to maintain accessibility of the items during shortages.

Meeting these requirements allow companies to encounter fewer operational risks in the long term while deploying advanced designs in a streamlined fashion.

Benefits of a Strategic Sourcing Partnership Defining the boundaries of simple transactional purchases allows customers in strategic partnerships to take advantage of allied values that come with integrated services switching power supply suppliers.

what strategic sourcing offers:

System Optimization: Those with extensive catalogs deliver optimal results based and specially designed to have specific load profiles, voltage tolerances, and thermal conditions.

Quicker Troubleshooting: Root cause analysis can be expedited by well-acquainted suppliers who are already knowledgeable about your application context enabling them to offer proactive suggestions when issues arise.

Customization Assistance: Although a client may need a bay with a specific mounting form, or a supply that works within a wide range of temperatures, established partners can meet these requirements without leading times that are deemed excessive.

Training and Documentation: Access to user manuals, technical papers, and other documentation helps your team make the right decisions without being reliant on external consultants.

Organizations that have a more constructive approach towards their suppliers, treating them as strategic partners, often have stronger and more resilient automation architectures.

Suppliers looking to foster a sustainable work relationship should aim for future-proof workflows.

The advancement of automation technologies necessitates an upgrade in power infrastructure. Tomorrow’s machines, from edge computing and IoT sensors to AI control systems, will require smarter, more efficient, and more flexible power supplies.

Suppliers that stay ahead of these trends, such as Automation Components Inc., tend to offer better guidance on integration and support for next-gen hardware, energy-saving topologies, and smart grid protocol interoperability.

Shifting towards an Industry 4.0 approach requires embracing modularity, interoperability, and reliability. Only bold suppliers, armed with a proactive development strategy, can capture these fluctuating demands. Future prerequisites like remote diagnostics or digital twin instrumentation will rely on a solid base.

Conclusion: The concealed capability offered by strategic sourcing.

In a world where every machinery parameter is essential, automation does not make an exception. Opting for a vendor providing switching power supplies is not just a procurement decision—it is a pledge towards system efficiency, enduring success, and streamlined operations.

A trained supplier provides catalog browsing but also offers deeper access to advanced information—including business continuity planning. For organizations that seek to thrive in high demand, automation components inc guarantees that power distribution will never be a restricting factor.

Choosing partners based on their technical complexities, their specific model of service, as well as their long-term plans turns the purchase into an investment rather than simply buying a part, which can transform into a performance partnership.